Here's the first part of the interview with Tom Lucas! This part covers the questions that were specific to my engine, while the next part (which I'll post later today) covers many of the general FE questions. EDIT: I've added a transcript of this recording below the video.

Unfortunately, the engine test stand's electric radiator fan makes noise throughout this video, so the audio quality isn't so hot. I'll post a complete narrative of this video later on for folks who might not want to wade through it, since it's not always easy to hear what we're saying.

As before, the WMV file will play almost anywhere while the high quality H.264 (AVI) file will play only on up-to-date computers.

Video: Tom Lucas at FE Specialties Interview, Part A: H.264 (75MB) WMV (69MB)

Note that I created the following video transcript by listening to it with my fallible ears and typing it with my fallible fingers. So I could have made some mistakes. Also, to convey the video content more effectively, I trimmed out some of my one-syllable, passive affirmations like, "Yeah," and various "uh"'s, "oh"'s, and grunts.

Please also note that this forum software includes the word, "wrote," after each quotation, yet Tom didn't write any of this--this is a straight transcript from our spoken conversation.

Begin Video Transcript

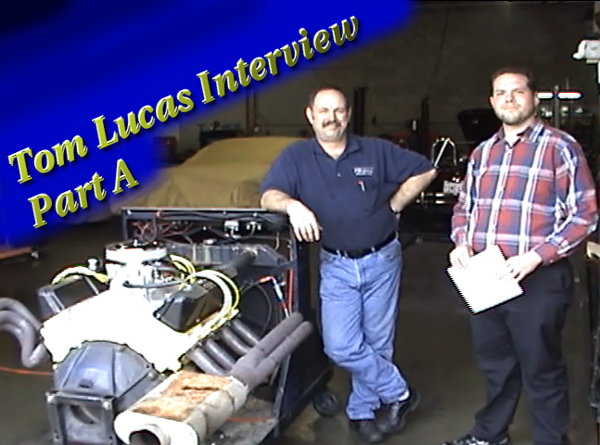

Robroy: Hi I'm Robroy, and I'm here with Tom Lucas at FE Specialties in Sacramento.

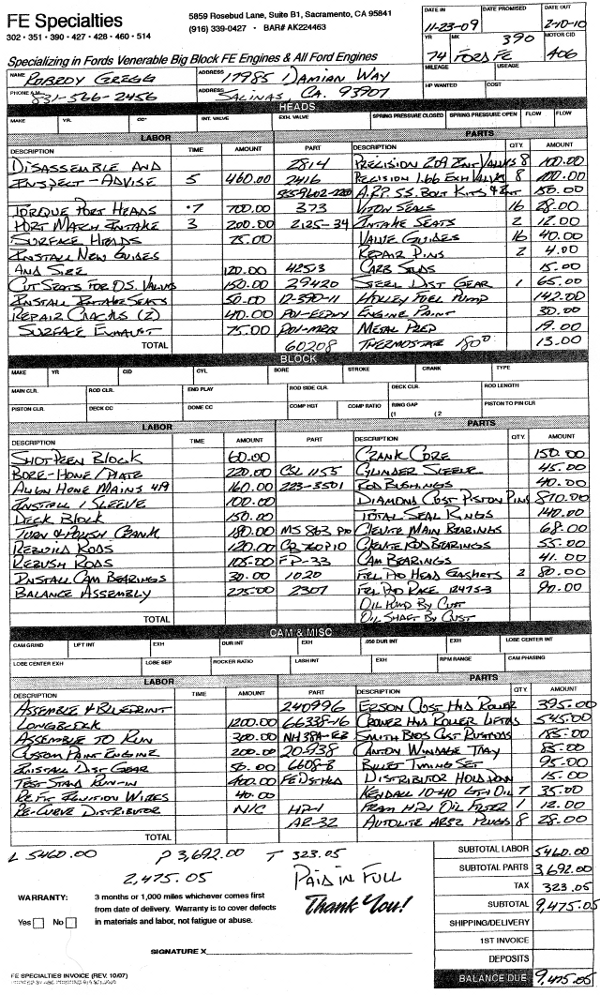

Robroy: And I have some questions prepared for Tom about this beautiful 406 FE that he just built for me. So Tom, what are the biggest differences between this design, which you put together, and the design that was in the previous engine that I brought to you?Tom Lucas at FE Specialties wrote:How you doin'?

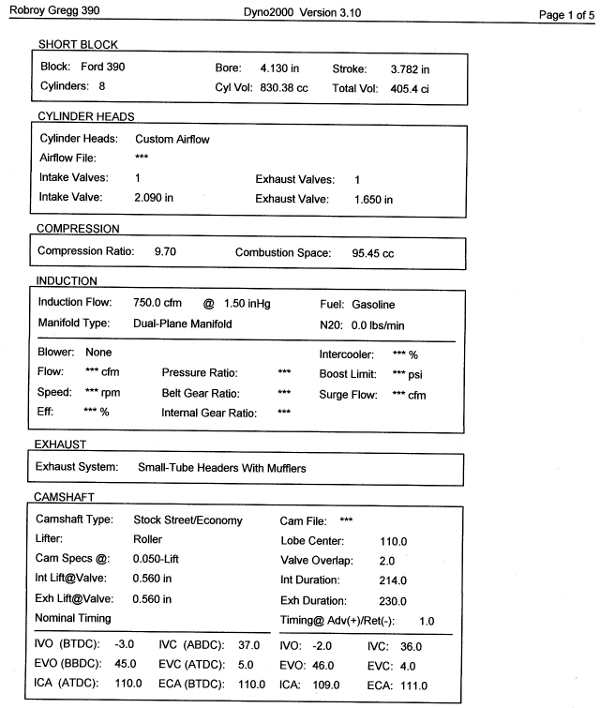

Robroy: OK, great. So um, how would the truck behave with this design, compared to the initial design. Like what differences would you see in this truck, with its wide ratio and all that?Tom Lucas at FE Specialties wrote:OK, well, the previous design was a low compression, big cam, unported, intake manifold motor that basically was not a balanced, engineered package for what you're trying to accomplish.

The cam was too big for the compression, the heads had no porting or relieving done, stock valve size, inverted seats, so basically, the motor how it was built wanted to run in the 800 to 3400 RPM range, and the camshaft that was chosen, wanted to run in the 2500 to 6000 RPM range. So you had basically an out of balance motor. So that would be the main difference.

Robroy: It does, yeah [not true, since it was 95% over my headTom Lucas at FE Specialties wrote:Well with the first motor, it was gonna be a little temperamental off idle, it's gonna hesitate a little bit, you were gonna have to bring RPMs up a little bit, above say eighteen hundred, you know two grand, somewhere in there, to get the engine the engine to be happy.

This motor's designed to be basically just off idle, happy, as soon as you hit the gas. And that will depend somewhat on the carburetor tune as you look in to as you proceed.

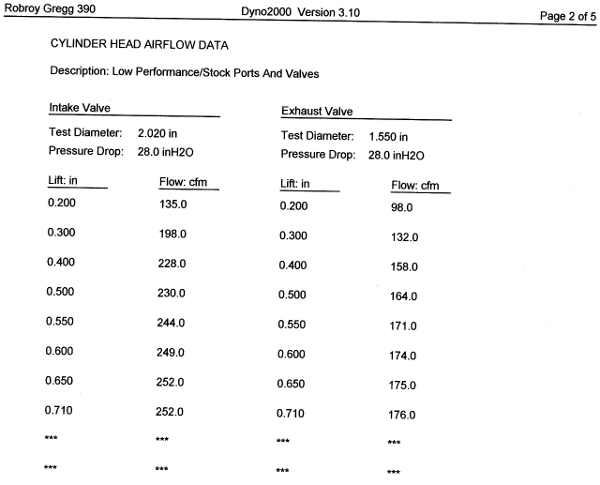

So this is a torque motor. The other motor was a stock motor trying to be combined with a hot rod motor and it wasn't. So this was engineered--the way I ported the heads, the size of the porting, the ratio of the runner as it runs in to the bowl area underneath the valve, the fact that we put the bigger valves changed that ratio a little bit, it gave you a little better low lift flow.

I didn't make the ports huge, as you'll see in some of the pictures, but the runner size if fairly constant for torque, that's like the old Ram manifolds of the Mopars, where they had the carbs sitting on either side of the valve cover, and this long Ram manifold, what that was, those were big engines in big, big cars, and they use that long runner length as a tune for torque. It broadened the torque range, it allowed more upper RPM horsepower but it also fed the cylinders well low. So this is similar [to] what I did here--what I do.

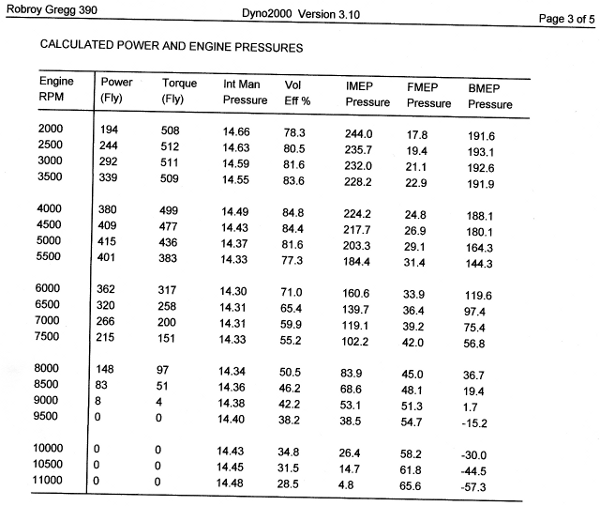

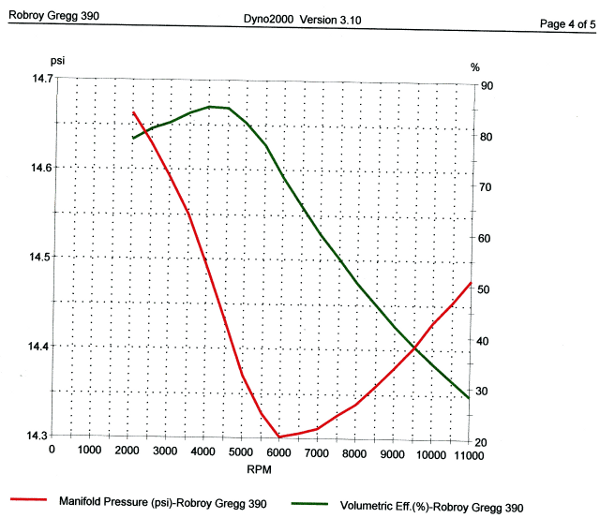

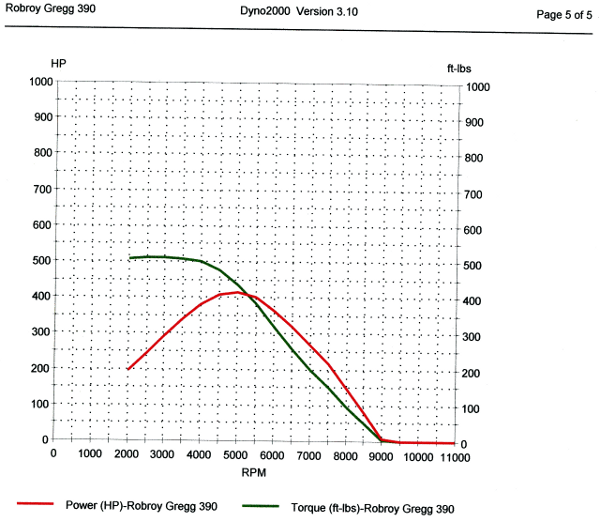

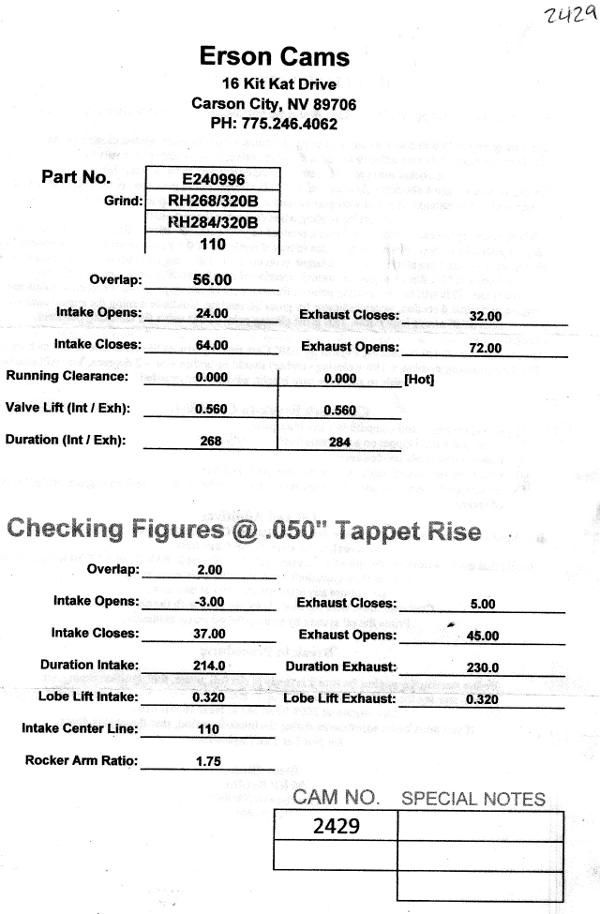

So now you have a split duration camshaft that's relatively small on the intake side for idle vacuum, but then you have the same split that's generally found in Cobra Jet cams, which the Ford engineers spent a lot of time figuring out how these motors respond, and that's due to the valve seat angle, this has got a 30 degree intake seat now instead of a 45, so that's a little different for low lift, and there's all sorts of uh, you know I could go on and on about this, but this motor now is built to be efficient from just off idle, up to about five grand--forty eight, five grand.

And because of the porting and the runner freedom, I guess the peak power is supposed to be around 5,200. So the more effective the heads are the more free flowing but small the longer your usable RPM range will be. So, does that make sense?

Robroy: YeahTom Lucas at FE Specialties wrote:Right, yeah you need--the lower the torque the better. When you drop the gear to the next gear, the motor's not going to be unhappy.

Robroy: So Tom, what advice would you give on timing the engine? What settings would you recommend, and so on?Tom Lucas at FE Specialties wrote:We like happy motors.

Robroy: OKTom Lucas at FE Specialties wrote:Well it's timed now.

Robroy: Oh, OK.Tom Lucas at FE Specialties wrote:And we had to verify your balancer, and I'll go over that with you, but FEs with stock combustion chambers generally like between 38 and 40 degrees total advance.

So you set the total--that's what you're concerned about with a centrifugal distributor on an MSD, you're worried about your total, not your initial. The initial just plays in to your RPM idle and the transfer slot position. And I think you're pretty close here. But we prefer the Holley carb' because that setup in the Holley is closer to what we like to set the initial timing at but not have the carb be too rich or too lean at that setting in the transfer slot. So the Holley carb does a better job of emulating where the FE wants to idle as far as the calibration of the carb.

Robroy: Oh.Tom Lucas at FE Specialties wrote:These carburetors [Edelbrock] are basically old AFB Carters that were on Mopars.

Robroy: Yeah!Tom Lucas at FE Specialties wrote:That's what they are. Just FYI.

Robroy: Oh OK!Tom Lucas at FE Specialties wrote:And back in the 70's, everybody took the Carters off and put Holleys on.

Robroy: Yeah! Well that might be what I wind up doing ultimately.Tom Lucas at FE Specialties wrote:And went faster!

Robroy: PossiblyTom Lucas at FE Specialties wrote:Well.

Robroy: Okay, so when I go to play around with the carburetor, do you have any specific advice that I might follow other than the instructions that came with it, for tuning it, and so on?Tom Lucas at FE Specialties wrote:Yeah, they've done, they've actually helped them out quite a bit.

Robroy: OKTom Lucas at FE Specialties wrote:Well you always want to be leaning on the rich side, and then backing off. Okay, you don't want to lean on the lean side, and detonate the motor, you're at 9-7 to 1, so it's not real--10 to 1 with an iron head is border-line. 9-7 gives you a little leeway with premium gas. But you want to start off a little fat, and then back up a little bit.

Robroy: YeahTom Lucas at FE Specialties wrote:Okay? And then, if you back up, and it gets faster and then you back up a little more, and it is goes slower, then you want to go back to, that second setting, do you follow me?

Robroy: OkayTom Lucas at FE Specialties wrote:But you want lean on the fat side of the balancing act.

Robroy: 'cause that's the safe side.Tom Lucas at FE Specialties wrote:So...

Robroy: Oh, OkayTom Lucas at FE Specialties wrote:You haven't touched it now, right? It's just stock out of the box. And this is richer of the two 750's.

Robroy: Oh, okay.Tom Lucas at FE Specialties wrote:So, what I would do would be to go up a size on the rods, and the spring is gonna be...that's gonna be how you determine how it drives. You're gonna have to drive it first, and that in the, you know, the spring for the rod raise, determine when that rod raises. And you'll have to drive and load the truck, before you start messing with the spring size.

You might have to go to a jet change, really, you need to have somebody like myself--break the motor in, get some miles on it, and then do a plug read, and see where the motor is, and then plug read each time you do a change.

Robroy: YeahTom Lucas at FE Specialties wrote:Okay, that's the way it's supposed to be done.

Robroy: Oh, okayTom Lucas at FE Specialties wrote:And then the actual best way would be put it on a chassis dyno with an air/fuel mixture ratio and you'll know exactly what to do.

Robroy: Oh.Tom Lucas at FE Specialties wrote:So, maybe what you could do is break the motor in, get around a thousand miles on it, then take it to a chassis dyno--a competent one. We have one up here it's SVS, that I'm real happy with. But they have to use a very high quality wide-band O2 sensor, so that they're measuring what the air/fuel mixture ratio is accurately. And then you can tune that carburetor in different settings: part throttle, part cruise, full throttle, heavy load, you guys can go and do it all at once.

Robroy: Okay. So after I run it for what, around a thousand miles, and then I want to have that done?Tom Lucas at FE Specialties wrote:So, that's really the way it should be done.

Robroy: Okay, great.Tom Lucas at FE Specialties wrote:Yep.

Robroy: Great. So, if I hook a vacuum gauge up to the intake manifold, about how much should I expect to see at idle, when things are operating properly.Tom Lucas at FE Specialties wrote:And you're gonna probably find some performance there, so it'll be worth it.

Robroy: About sixteen?Tom Lucas at FE Specialties wrote:Sixteen.

Robroy: Okay, So um, how fast can this engine spin before there are any problems--what's it's red line for the tachometer...approximately?Tom Lucas at FE Specialties wrote:16, would be a good...16, 16 and 1/2, something like that.

Robroy: As long as it's under 58'Tom Lucas at FE Specialties wrote:5,800 RPM is where you want to keep this.

Robroy: Great. So um, for my temperature gauge, where should I be looking for trouble, like how hot can it get before there's any kind of problem, would you say on this engine? More or less.Tom Lucas at FE Specialties wrote:Under 58'. This is a hydraulic roller with--I didn't put the real heavy spring in it, so you're gonna want to shift it no later than 58'. But, you're peak power is gonna be around 5,1', 5,200, so there's no reason to really go past 5,5'. See, you're gonna be going down--you can go a little over the peak power,

'cause that will bring your torque up when you change gears. But yeah 5,800 would be your red line.

Robroy: Got it. 220. That I will do.Tom Lucas at FE Specialties wrote:Yeah 220. If you see it get above that, you need to pull over and let it cool off.

Robroy: Okay. So um, given that it has the high volume pump, and windage tray installed, about how, what kind of oil quantity would you recommend.Tom Lucas at FE Specialties wrote:But, it runs really cool. Every time I put a motor on this test stand I can kinda generally get an idea by how quick it heats up, by how long I've had it running. And this thing is running quite [cool]. So, you shouldn't ever see any issue.

Robroy: Okay, would you recommend going beyond that at all, because of, let's see, what was it...the issue we were describing, since you know I'm going to race this, on the uh, on the Leguna Seca, that real twisty track, ya know.Tom Lucas at FE Specialties wrote:It's 5 and 1/2 quarts in the pan, and a quart for the filter. So 6 and 1/2.

Robroy: With a bunch of bails of...big bails of hay in the backgroundTom Lucas at FE Specialties wrote:

Robroy: Yeah I'm gonna chase Ryan, with this, uh.Tom Lucas at FE Specialties wrote:You're gonna chase Ryan--chase Ryan down to Baja.

Robroy: Right foot out the door...Tom Lucas at FE Specialties wrote:You know, I don't think it would hurt it to go to six quarts total. But here's the deal. You can check, you can put six quarts in it--run the motor, and pull the dipstick out--you shut it off, pull the dipstick out, if you see any bubbles on the end of the dipstick that means that the oil's getting aerated because it's a little too much in there. And you don't want that.

So, but you should be fine, 5 and a half quarts, with that high volume pump, is adequate. You're not gonna be, you know, sticking your left foot out the door going around turns I don't think. I could be wrong.

Video Transcript CompleteTom Lucas at FE Specialties wrote:

Thanks very much to Ryan (1971Ford) for operating the camera throughout this interview!

Robroy