Got some mew tires on the tow rig this morning and had to get a few parts rounded up but still managed to have a pretty productive day in the garage.

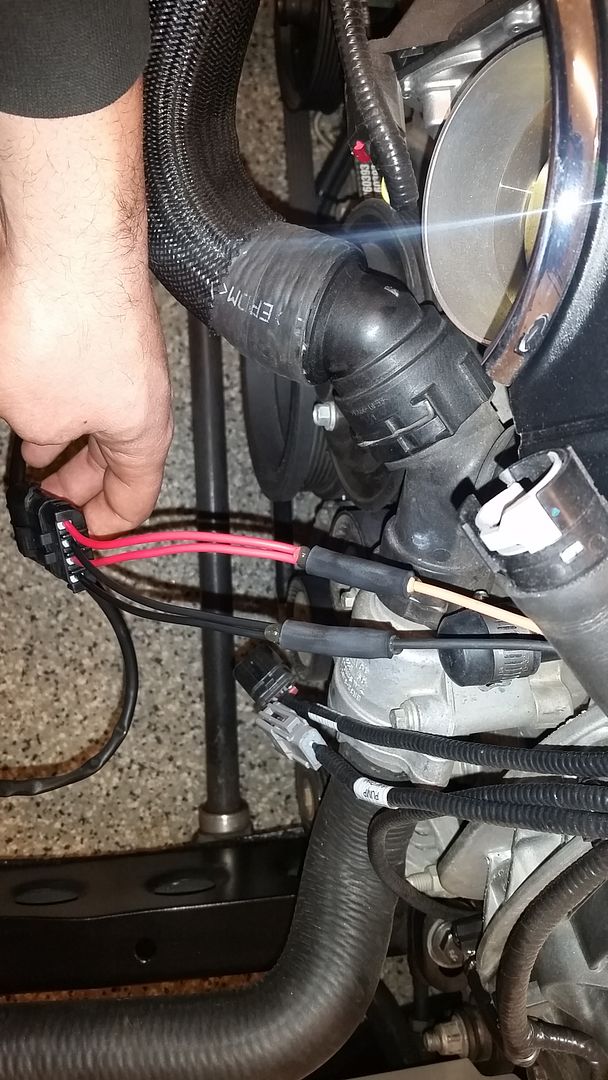

Started off tucked up under the passenger fenderwell building out the rest of the power harness. I am running (2) 8 ga fuse holders at the battery to feed the main truck power, my fuse panel and the ford racing stuff. I am running a 60 amp fuse on each, they should not be pulling that much power though. This is really just to protect the wire from the battery to the next fuse. Also fused the two other 12v + wires from the truck harness up to the battery.

It took a little bit of finnagling but the harness up under the fender, that likely nobody will see ever turned out really nice. You barely see any wiring for the battery or main power anywhere on the truck. Also did the headlight wiring harness on this side and the passenger side as well.

My mess.

Harness built, fuse holders in place, ends all on and heat shrink in place.

You can see how I hung this in place, its got these insulate p clips and they hang from the bottom of the fender bolts and have a nut on them securing them out of the way.

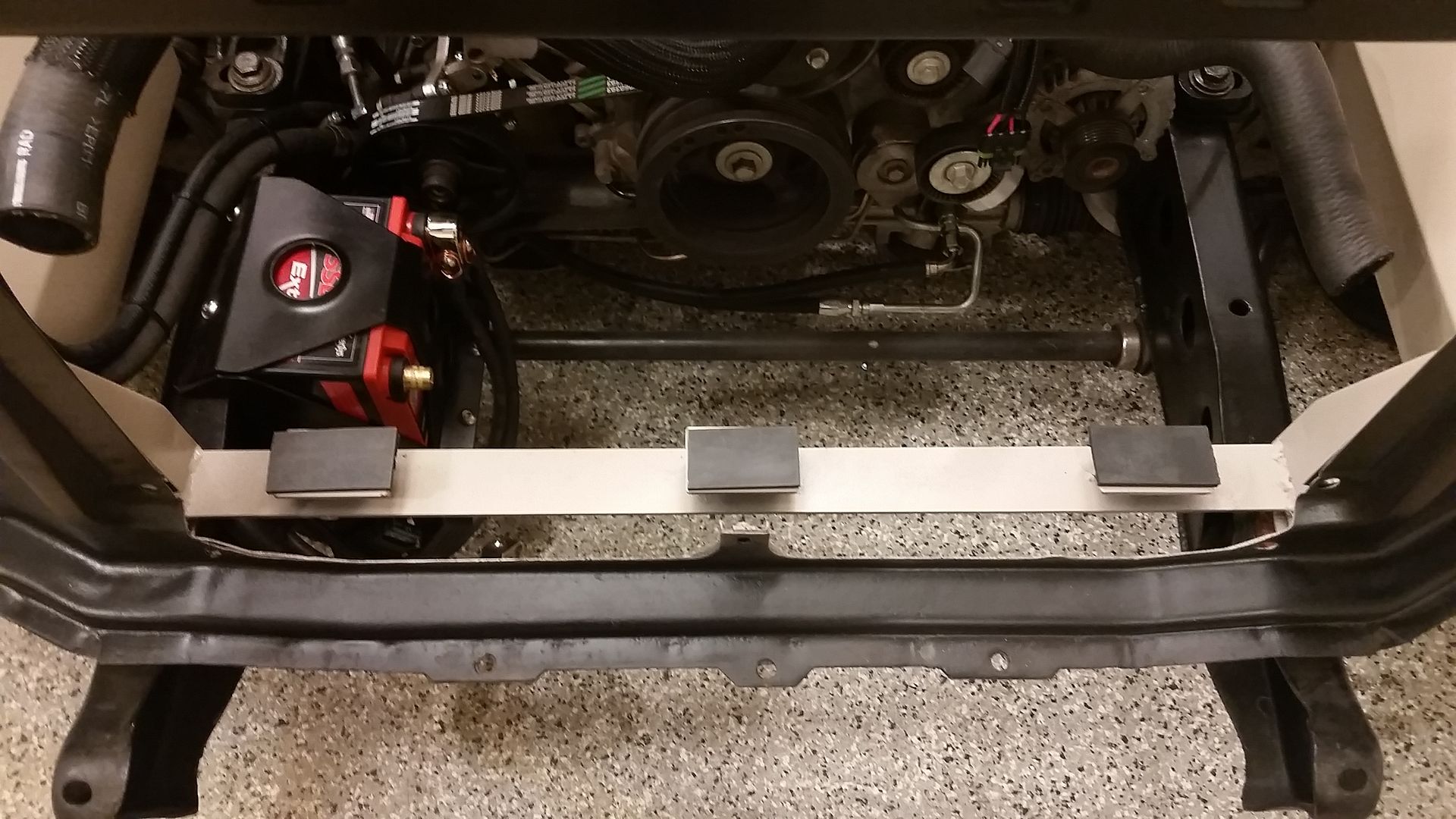

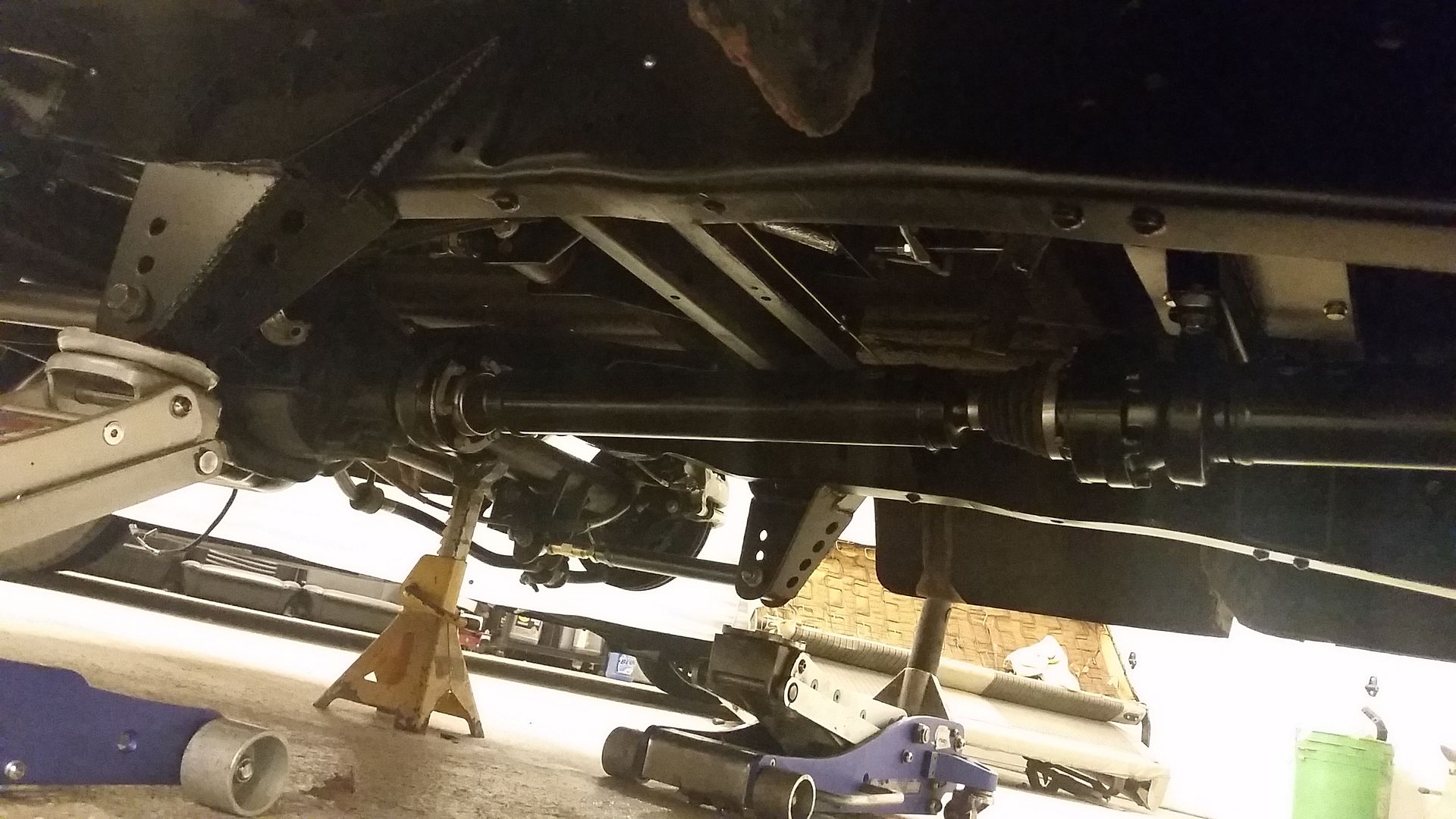

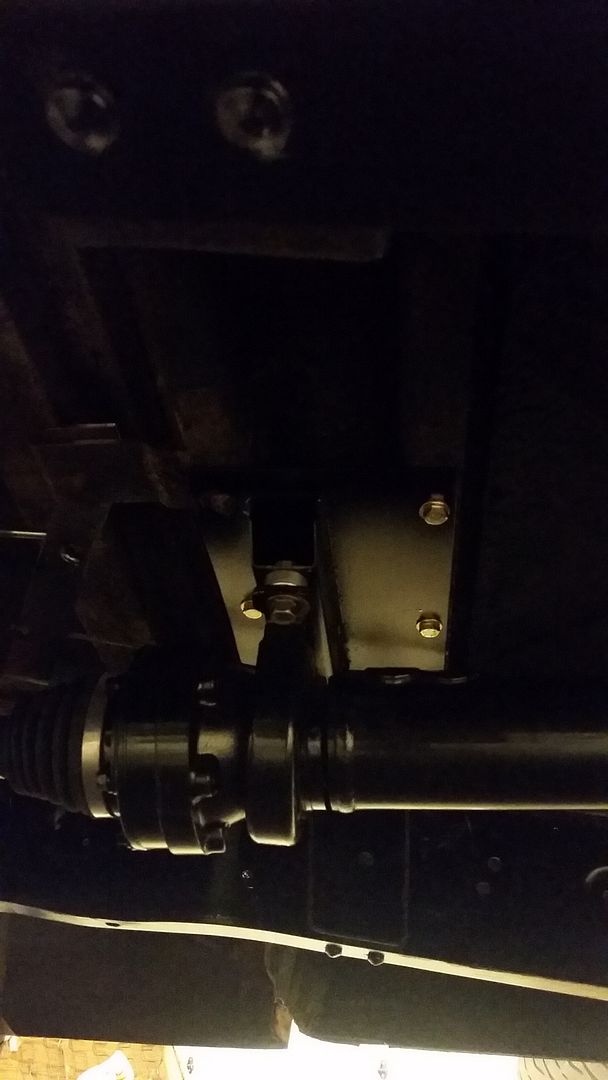

Once I got the passenger side wiring buttoned up, I could hang the drivers side fender on there. and I got to pull it outside for the first time in months, resembling something like a truck again

And Pulled it back in the garage this time with a little more work around room. Not sure why I have never done this before.

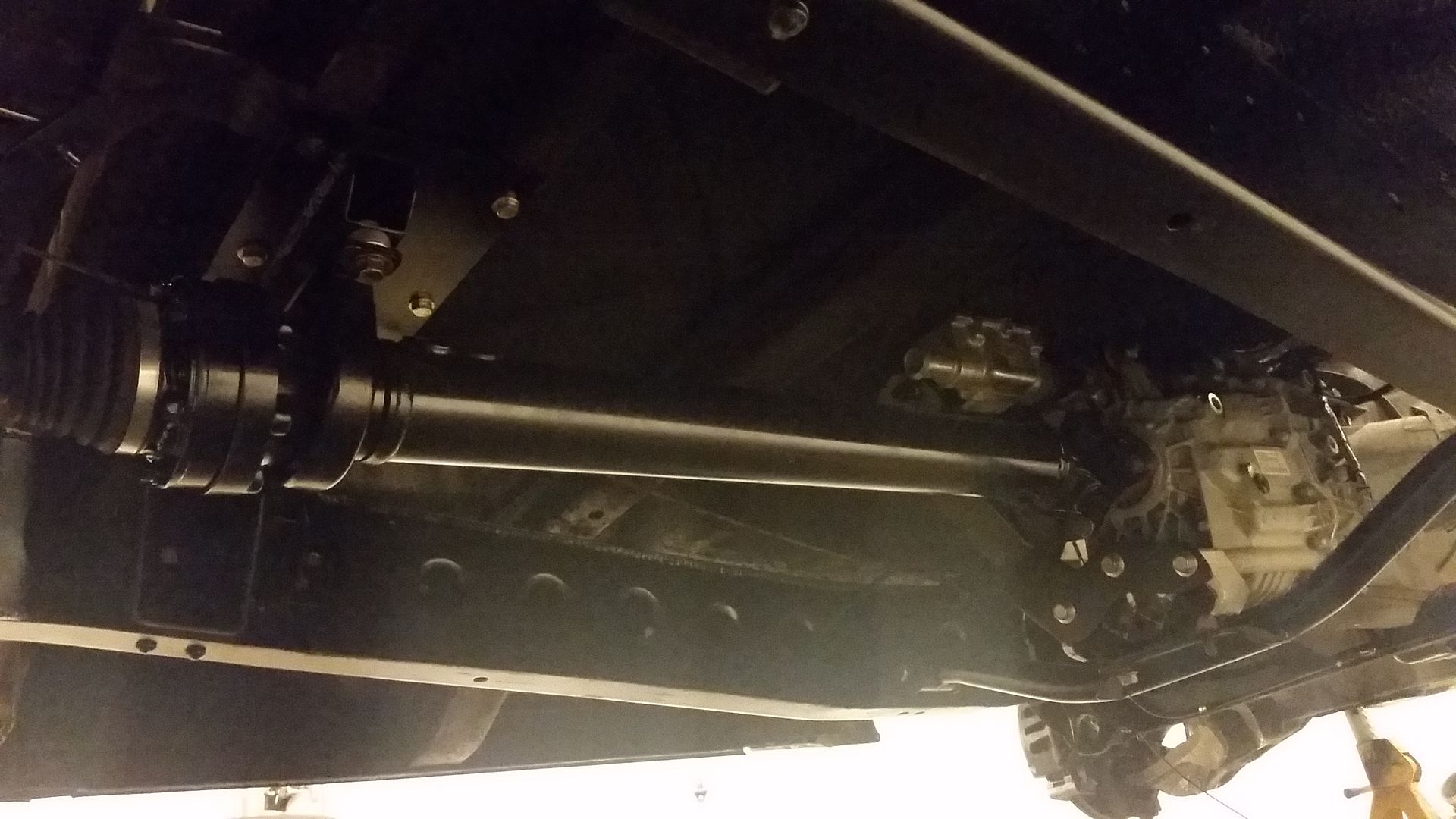

With the exception of a few hose clamps and an air filter, this is completely wired and plumbed. I have to wire in the fans still but the wires are right there, just need to hook up.

So with that tackled and things moved around in the shop it was time for dinner,

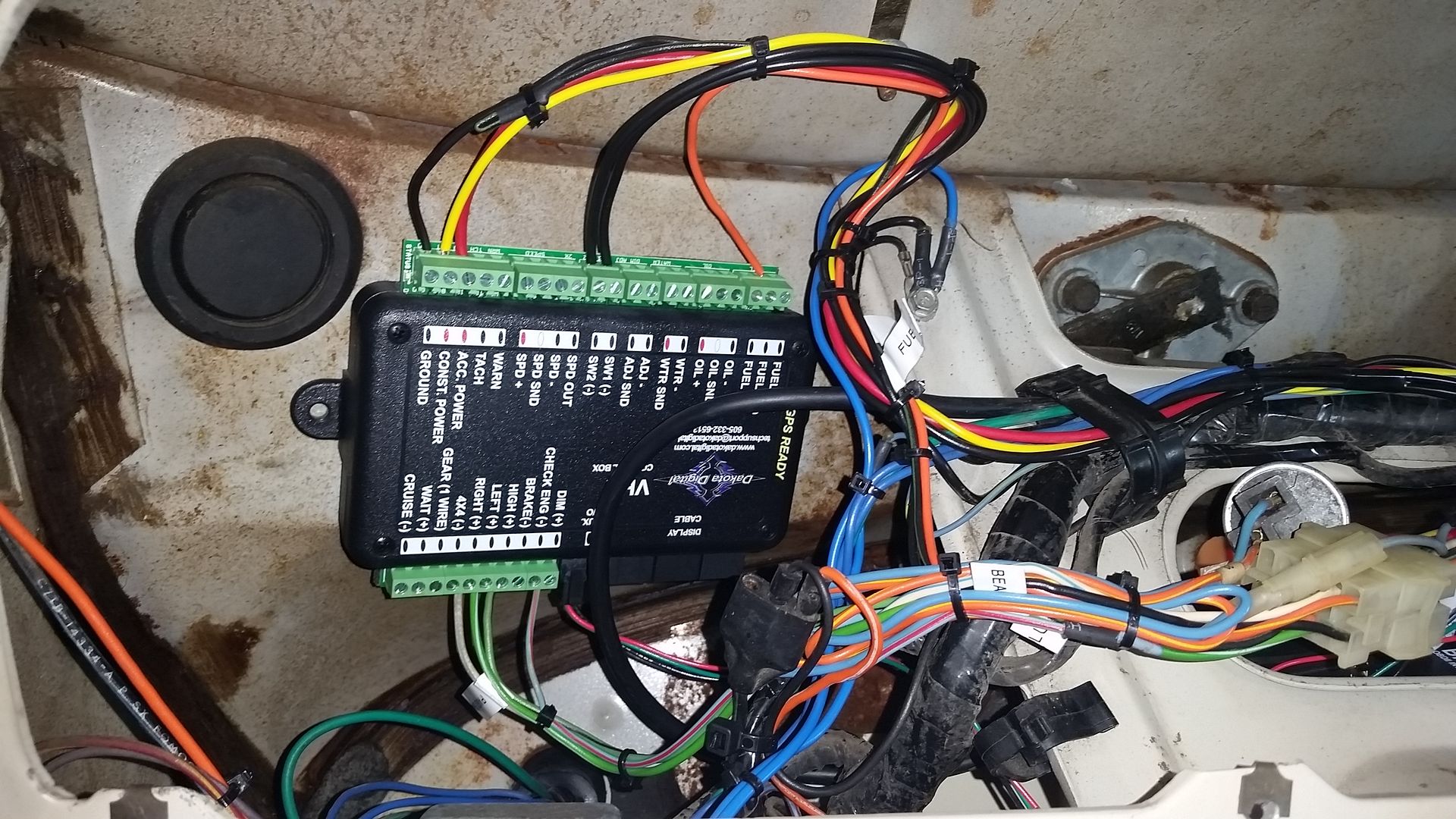

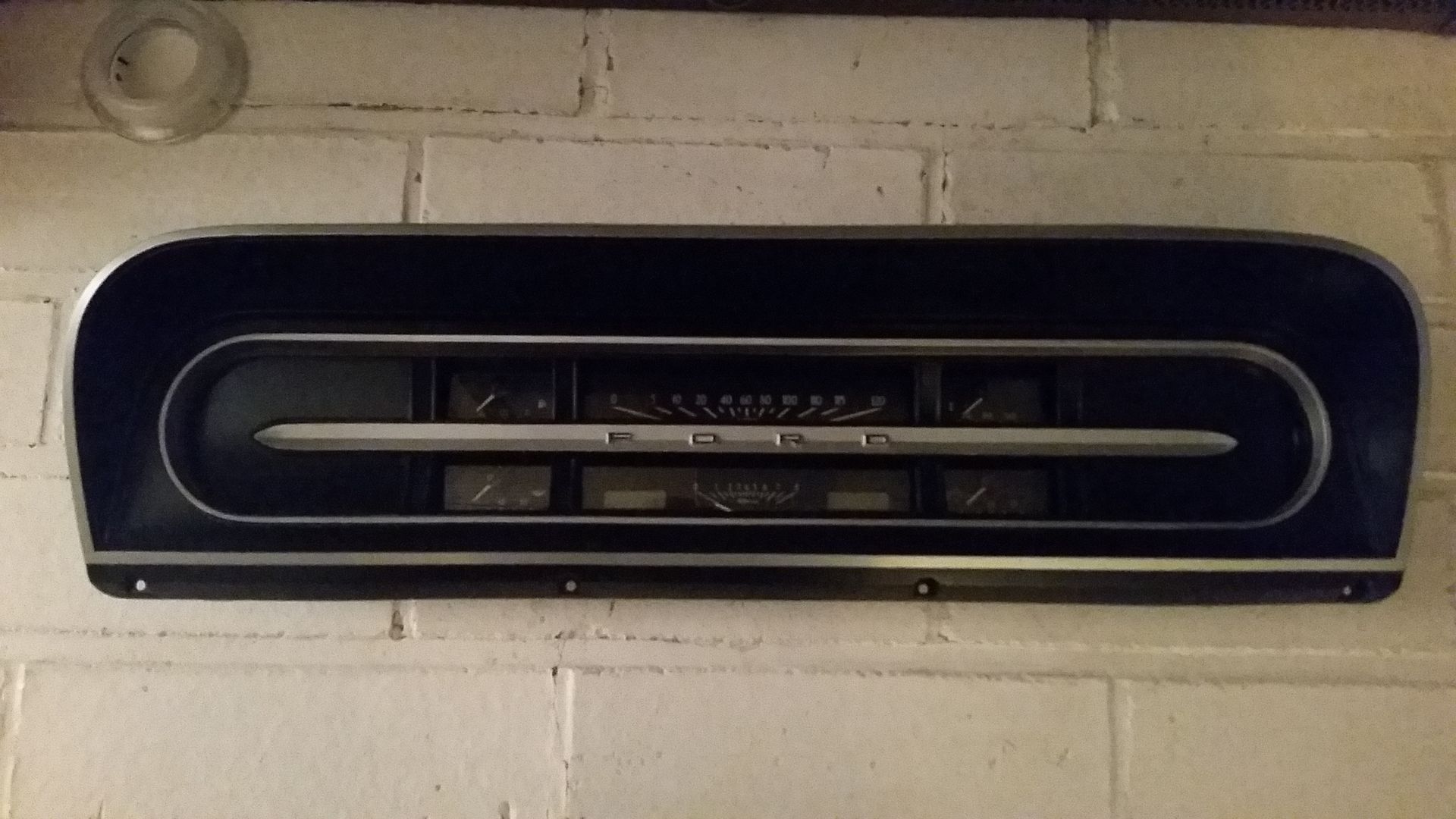

I came back out to tackle some of the interior wiring I needed to button up. I got the VHX Stuff out of the box and got to it. I have the Ford motorsports Coyote control pack all wired in now, switched 12 v, start and 12v+ are all done, switched 12v to the oss, switched 12v to the VHX is terminated and most of the wiring is terminated at the VHX. I have to run from my fuse panel to the VHX panel tomorrow and get it mounted and button up a few other wires at the back of the cluster. I cleaned up a ton of stuff in the instrument cluster and unpinned any wires I did not need for the VHX stuff to run, this way I have a nice little pigtail I can still disconnect.

More Wiring fun..

Running wires and cleaning up the under dash wiring All connections are soldered and heat shrunk on the truck.

Going to try and get the grilled on and button up all of the remaining wiring on this turd.

Sean