390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Moderator: Ranchero50

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Gaskets leak... Ultra black...

Looks great, We're actually making about the same progress, just I'm always working on something else too and I'm sure you are too.

Jamie

Looks great, We're actually making about the same progress, just I'm always working on something else too and I'm sure you are too.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- FreakysFords

- Blue Oval Fanatic

- Posts: 815

- Joined: Mon Mar 09, 2009 9:58 pm

- Location: Gadsden Alabama

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Nothing more than an opinion here, but personally, I'd clean off the old, set the new in place and depress it into the passage holes to mark the area for new cuts. Then I'd cut it, oil coat it, sit it on something clean and let it soak a few minutes, then install. Clean up the mess and go on to the next thing

Anticipation building nicely

Frank

Anticipation building nicely

Frank

Darlin 69 Ranger 390 4v, PS, DS II, disc front, 3G alternator, 67 mirror.

-

Fordnatic

- Preferred User

- Posts: 274

- Joined: Wed Dec 17, 2008 7:29 am

- Location: Anchorage, Alaska

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

An easy way to match the holes on the gasket is the same method I've used many times to make one from scratch. Just stick the gasket in place and take the ball end of a ball peen hammer and gently tap around the edge of the holes in the block. Normally the sharp metal edge will easily cut the gasket material for a perfect fit. I've used this for the outside edge also when making gaskets from scratch from a roll of gasket material. If it doesn't cut all the way through it certainly will make a perfect mark that you can use to cut it with.

70F100: 410 Merc with tri-power, close ratio toploader, 4.56 detroit locker 9"

68F100 4x4: 390, 4 spd/NP 205, Rancho 4" urethane susp, 35x12.50 All Terrain T/A's

55F100

01F150 Daily Driver: TP tunes, AF1 intake, elec fans, Magnaflow exh, underdrive pulleys, Centerlines

68F100 4x4: 390, 4 spd/NP 205, Rancho 4" urethane susp, 35x12.50 All Terrain T/A's

55F100

01F150 Daily Driver: TP tunes, AF1 intake, elec fans, Magnaflow exh, underdrive pulleys, Centerlines

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good afternoon 70_F100, Alvin, Jamie, Frank, and Fordnatic, thanks for your fantastic replies!

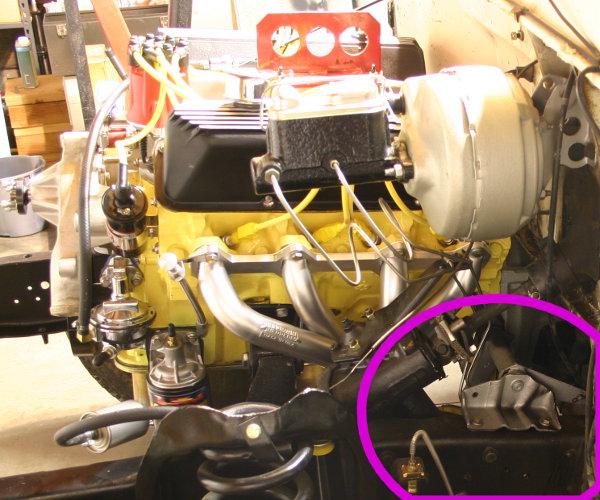

Yesterday and this morning I managed to get the engine installed, aligned, and torqued down! You can click on any of these photos to see much larger, higher definition versions.

Here are a couple of photos I took after getting the engine to sit happily in the frame; I hadn't aligned it to the frame yet at that time.

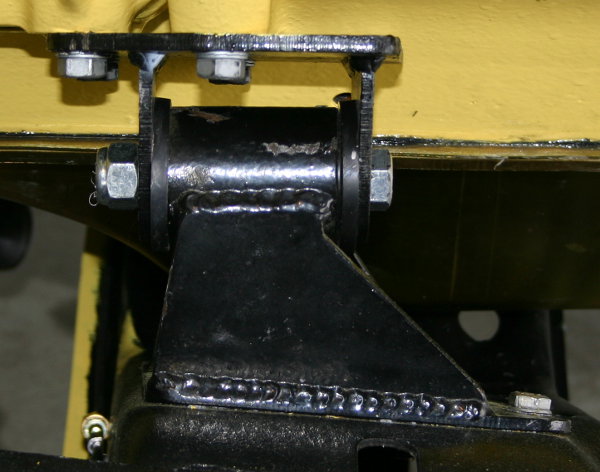

I moved the transmission crossmember back in to its ideal place and torqued its to bolts to 65 ft/lbs.

Here I'm measuring and doing the alignment procedure described to me by Jamie in FE and T18/C6 mounts from Autofab, plus frame alignment. Having gone through this at least once before sure makes a huge difference--the alignment was complete in two or three hours of fiddling around.

I torqued the bolts that held the Autofab mounts to the engine block to 50 ft/lbs, then torqued the fat bolt that runs through the polyurethane bushing to 35 ft/lbs.

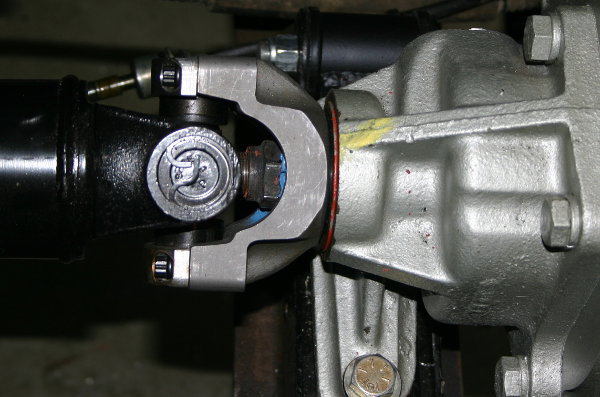

And the driveshaft's now all hooked up, thanks to the instructions I received last Fall in Should U-joint retention bolts really be 13-17 ft/lbs?

I torqued the two bolts that run through the transmission mount's polyurethane bushings to 45 ft/lbs; they probably didn't need to be that tight but I didn't want them to come loose, and they're big so I thought they could take it.

70_F100, Alvin, Jamie, Frank, and Fordnatic, thanks for your ultra fantastic advice!

Robroy

Thanks very much!70_F100 wrote:Great progress, Robroy!!

Okay, thanks! I may wind up leaving the old gasket then. I'll poke around at it and see how solid it feels and looks.70_F100 wrote:As for the gasket, make sure it's wiped off well and the filter adapter didn't pull any of the material off with it, and if all looks good, just bolt it back on.

The engine hasn't been run long enough for heat to have given the gasket "memory".

That's true!70_F100 wrote:And, if it leaks a little,it's not that big of a deal to replace it later.

Okay, thanks for letting me know!70_F100 wrote:My guess, though, is that you won't have any problem whatsoever with the old gasket.

Okay, thanks Alvin! My disinclination towards clearancing the gasket was based more on the avoidance of complications than the avoidance of work, since I've never cut a gasket like this before.Alvin in AZ wrote:1 vote for yes, so far....so clearance it silly.

That sounds like it would work well! So far the method that seems coolest is Frank's and Fordnatic's idea of using the oil passages themselves to mark the cuts on the gasket.Alvin in AZ wrote:I'd prob'ly use a sharp knife with the gasket on a piece of wood. It'd be cool to hear other guys methods on that tho.

I could give that a whirl instead I suppose. Thanks for mentioning this possibility! My only concern would be about the oil filter adapter sticking to the block, and being rather hard to pull apart later on.Alvin in AZ wrote:{edit} What about no gasket at all? ...just use "gasket maker"?

So far, it doesn't look ripped to me, but I'll look at it more closely if I decide to skip replacing it.Alvin in AZ wrote:Ok, 70 sez to ignore the fact it's ripped? LOL{edit} Looking closer not sure it is ripped.

I see! I might already have some Ultra Black on my shelf. Am I correct in thinking that Ultra Black might make the adapter stick to the block in a somewhat stubborn way?Ranchero50 wrote:Gaskets leak... Ultra black...

Thanks! I keep thinking I'll reform my habits and spend a regular hour on #50 every night, but it doesn't seem to work out that way; it's pretty sporadic. But I have most of today to make some progress, so y'all will be seeing some decent updates!Ranchero50 wrote:Looks great, We're actually making about the same progress, just I'm always working on something else too and I'm sure you are too.

Thanks for this idea Frank! Does soaking the gasket in oil make it more supple?FreakysFords wrote:Nothing more than an opinion here, but personally, I'd clean off the old, set the new in place and depress it into the passage holes to mark the area for new cuts. Then I'd cut it, oil coat it, sit it on something clean and let it soak a few minutes, then install. Clean up the mess and go on to the next thing

Excellent!FreakysFords wrote:Anticipation building nicely

That seems quite clever Fordnatic, thanks for letting me know about this method! Should I replace the gasket I think I'll try this out. I'll be sure to be super careful with the ball peen hammer!Fordnatic wrote:An easy way to match the holes on the gasket is the same method I've used many times to make one from scratch. Just stick the gasket in place and take the ball end of a ball peen hammer and gently tap around the edge of the holes in the block. Normally the sharp metal edge will easily cut the gasket material for a perfect fit. I've used this for the outside edge also when making gaskets from scratch from a roll of gasket material. If it doesn't cut all the way through it certainly will make a perfect mark that you can use to cut it with.

Yesterday and this morning I managed to get the engine installed, aligned, and torqued down! You can click on any of these photos to see much larger, higher definition versions.

Here are a couple of photos I took after getting the engine to sit happily in the frame; I hadn't aligned it to the frame yet at that time.

I moved the transmission crossmember back in to its ideal place and torqued its to bolts to 65 ft/lbs.

Here I'm measuring and doing the alignment procedure described to me by Jamie in FE and T18/C6 mounts from Autofab, plus frame alignment. Having gone through this at least once before sure makes a huge difference--the alignment was complete in two or three hours of fiddling around.

I torqued the bolts that held the Autofab mounts to the engine block to 50 ft/lbs, then torqued the fat bolt that runs through the polyurethane bushing to 35 ft/lbs.

And the driveshaft's now all hooked up, thanks to the instructions I received last Fall in Should U-joint retention bolts really be 13-17 ft/lbs?

I torqued the two bolts that run through the transmission mount's polyurethane bushings to 45 ft/lbs; they probably didn't need to be that tight but I didn't want them to come loose, and they're big so I thought they could take it.

70_F100, Alvin, Jamie, Frank, and Fordnatic, thanks for your ultra fantastic advice!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good afternoon!

I spent some time preparing to install the driver's side header, but noticed some gasket issues that I'm stuck on--I updated ye olde Rough head exhaust surfaces, gaskets, and avoiding leaks with all the details!

Robroy

I spent some time preparing to install the driver's side header, but noticed some gasket issues that I'm stuck on--I updated ye olde Rough head exhaust surfaces, gaskets, and avoiding leaks with all the details!

Robroy

- OldRedFord

- Blue Oval Guru

- Posts: 1314

- Joined: Tue Jan 29, 2008 11:37 pm

- Location: Hull GA

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

What engine lifting plate is that? Good progress!

Tim

1972 F350 flatbed drw c6/390

1967 F600 project truck

1972 F350 flatbed drw c6/390

1967 F600 project truck

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good evening Tim, thanks for replying!

Robroy

That's a Lakewood 33027 ($30 from Summit). It's very sturdy and (if I remember correctly) is USA-made. The only caveat thus far has been the relatively long distance between the tops of the crane holes and its top ridge. Tom's engine hoist couldn't grab it, because his hook demanded a more low-profile lift plate! It's no problem with my lifting tools though.OldRedFord wrote:What engine lifting plate is that?

Thank you very much Tim! I'm still working on it at this crazy hour.OldRedFord wrote:Good progress!

Robroy

- FreakysFords

- Blue Oval Fanatic

- Posts: 815

- Joined: Mon Mar 09, 2009 9:58 pm

- Location: Gadsden Alabama

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

robroy wrote:Thank you very much Tim! I'm still working on it at this crazy hour.

Robroy

Now I think I know why Kay's not big on the whole idea of my getting the shop done.

Darlin 69 Ranger 390 4v, PS, DS II, disc front, 3G alternator, 67 mirror.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good evening Frank, thanks for replying!

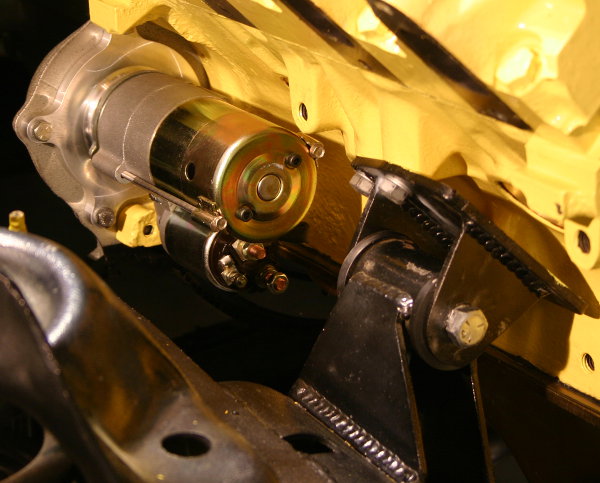

Here's the RobbMc starter back in action:

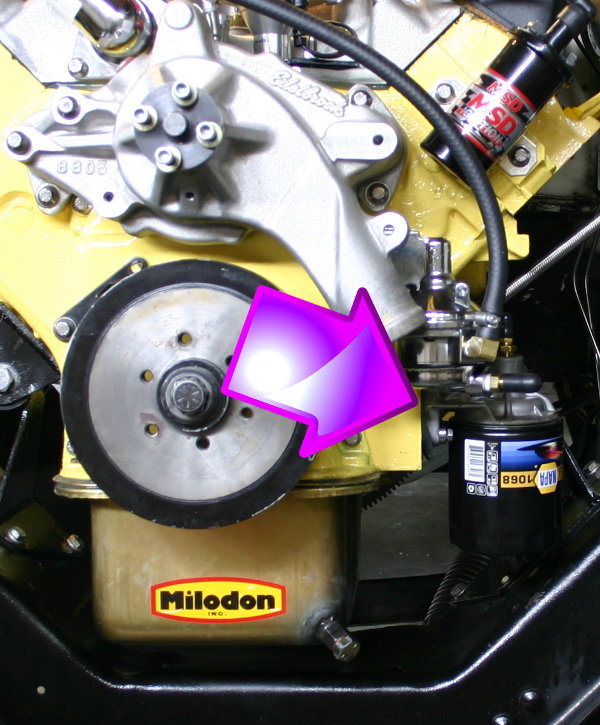

I re-installed the oil filter adapter and used one of my stubby, 3/4 quart WIX filters.

After taking a closer look at the "old" gasket, I went ahead and left it on there. It still felt pretty fresh and supple, and I received at least one vote for leaving it on (from 70_F100) so I knew doing so wasn't a purely insane choice! If it leaks later on, I'll have learned my lesson.

Thanks to the excellent help I've received in Rough head exhaust surfaces, gaskets, and avoiding leaks, the driver's side header is installed and torqued down! I also installed the clutch linkage and adjusted the clutch, re-using 70_F100's great advice in Clutch adjustment: 1-1.5" of pedal play or 1/8" fork play?.

Frank, thanks for your great reply!

Robroy

Thanks for being interested! And it's even later for you, if what they say about time zones is really true.FreakysFords wrote:still enjoying the build from another state at this crazy hour. ROFL.

That's understandable! Once complete, you'd stand in its door, wave, and yell, "See you on Christmas Day!"FreakysFords wrote:Now I think I know why Kay's not big on the whole idea of my getting the shop done.

Here's the RobbMc starter back in action:

I re-installed the oil filter adapter and used one of my stubby, 3/4 quart WIX filters.

After taking a closer look at the "old" gasket, I went ahead and left it on there. It still felt pretty fresh and supple, and I received at least one vote for leaving it on (from 70_F100) so I knew doing so wasn't a purely insane choice! If it leaks later on, I'll have learned my lesson.

Thanks to the excellent help I've received in Rough head exhaust surfaces, gaskets, and avoiding leaks, the driver's side header is installed and torqued down! I also installed the clutch linkage and adjusted the clutch, re-using 70_F100's great advice in Clutch adjustment: 1-1.5" of pedal play or 1/8" fork play?.

Frank, thanks for your great reply!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good afternoon!

Here's how the engine's looking today--it won't be long 'til it's fired up now! I updated Could I ask for advice on the March multi-groove pulley kit? after getting the March kit re-installed.

Robroy

Here's how the engine's looking today--it won't be long 'til it's fired up now! I updated Could I ask for advice on the March multi-groove pulley kit? after getting the March kit re-installed.

Robroy

- kyle ray

- New Member

- Posts: 149

- Joined: Mon Dec 24, 2007 5:32 pm

- Location: Baton Rouge, Louisiana

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

with your great pics,attention to detail , and fantastic updates. we are blessed that you have let us be a part of your build. You sir have done a great service for us all. I am very excited for you and cant wait till you fire it up.

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Robroy, which pilot bearing did you end up using?

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good afternoon Kyle and 70_F100, thanks for replying!

Kyle and 70_F100, thanks for your excellent replies!

Robroy

Thanks for saying so Kyle! It wouldn't have been possible for me to achieve anywhere near the quality and performance of this setup if it weren't for the amazingly generous guidance I've received here.kyle ray wrote:with your great pics,attention to detail , and fantastic updates. we are blessed that you have let us be a part of your build.

That's nice of you to say, yet I'm certain that I've been on the receiving side on FORDification much more often than I've been on the providing side. When people invest the time to share their experience with me, the least I can do is show my appreciation by letting them know how things turned out, and how their advice helped me!kyle ray wrote:You sir have done a great service for us all.

Excellent! I'm looking forward to that also. Yet since I've fired it up before, with its previous engine, what I'm really anticipating is my first drive up the street! That's what I've been working towards and thinking about for nearly two years now.kyle ray wrote:I am very excited for you and cant wait till you fire it up.

I wound up using an MRC 303SZZ ball bearing. There are detailed photos of it earlier in this thread, at the end of this post.70_F100 wrote:Robroy, which pilot bearing did you end up using?

Kyle and 70_F100, thanks for your excellent replies!

Robroy

- sport71

- Blue Oval Fan

- Posts: 560

- Joined: Sun Oct 02, 2005 6:17 pm

- Location: Texas, Mission

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Robroy, that looks great.

I have to ask you this. Is this your first real hotrod, like mine?

I have to ask you this. Is this your first real hotrod, like mine?

Those who do not learn the lessons of history, are doomed to repeat it.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good evening Ruben, thanks for replying!

I remember asking Tom what it was like to drive his 650+ HP Mustang, and he said, "You get used to it," and that the only thrilling/scary moment is the first three or four seconds of a launch, when the front lifts up and you can't see where you're going!

Robroy

Thanks very much!sport71 wrote:Robroy, that looks great.

Yes it is! I've never even gone for a short ride in sort kind of vehicle with this kind of alleged power before, so it will be a completely new experience for me. Yet I've driven enough mildly modified, sporty cars and trucks before to know that I love the thrill of having some extra power on tap.sport71 wrote:I have to ask you this. Is this your first real hotrod, like mine?

I remember asking Tom what it was like to drive his 650+ HP Mustang, and he said, "You get used to it," and that the only thrilling/scary moment is the first three or four seconds of a launch, when the front lifts up and you can't see where you're going!

Robroy

Last edited by robroy on Wed Apr 07, 2010 9:38 pm, edited 1 time in total.