390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Moderator: Ranchero50

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Roll the crank around with the tool attached and the bellhousing on, that will show if the tool is bent or perhaps not seated on the crank correctly.

Might have the take the spark plugs out so it will turn over easier.

Jamie

Might have the take the spark plugs out so it will turn over easier.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good afternoon Jamie, thanks for your excellent reply!

Jamie, thanks for your superb advice!

Robroy

Now THAT'S a good idea!!! Thanks very much Jamie.Ranchero50 wrote:Roll the crank around with the tool attached and the bellhousing on, that will show if the tool is bent or perhaps not seated on the crank correctly.

Okay, I'll do this if it's too difficult to turn with 'em in!Ranchero50 wrote:Might have the take the spark plugs out so it will turn over easier.

Jamie, thanks for your superb advice!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

'Afternoon!

The Yellow Jacket's significantly easier to turn over by hand than the previous engine, despite having higher compression. Maybe it takes less effort when I'm not grinding up camshaft lobes with my arm power. I didn't need to remove the spark plugs!

I didn't need to remove the spark plugs!

I turned the crankshaft and the Browell tool indication turned with it. At 180 degrees, the tool said that all the clearance was at the bottom of the opening instead of the top! So it looks like either the tool isn't seated properly on the end of the crankshaft (probable), or the tool's bent!

I'll pull everything off and give it another try.

Thanks for your extremely helpful advice Jamie!

Robroy

The Yellow Jacket's significantly easier to turn over by hand than the previous engine, despite having higher compression. Maybe it takes less effort when I'm not grinding up camshaft lobes with my arm power.

I turned the crankshaft and the Browell tool indication turned with it. At 180 degrees, the tool said that all the clearance was at the bottom of the opening instead of the top! So it looks like either the tool isn't seated properly on the end of the crankshaft (probable), or the tool's bent!

I'll pull everything off and give it another try.

Thanks for your extremely helpful advice Jamie!

Robroy

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Remember, keep it simple.

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good morning Jamie!

I have an unrelated question that I've been "saving up" for weeks.

I last filled #50's gas tank with about five gallons of 91 octane gas in late October, 2009. It's been sitting ever since. I know that gas deteriorates over time, so do y'all think I should:

Robroy

I'll try my best! Thanks again for your excellent help with the tip on turning the crankshaft. Advice from an experienced man helps to keep things simple!Ranchero50 wrote:Remember, keep it simple.

I have an unrelated question that I've been "saving up" for weeks.

I last filled #50's gas tank with about five gallons of 91 octane gas in late October, 2009. It's been sitting ever since. I know that gas deteriorates over time, so do y'all think I should:

- Siphon all the old gas out? OR...

- Add something in a can to the gas to improve its quality, then idle it through The Yellow Jacket? OR...

- Idle it through The Yellow Jacket without giving it a second thought? OR...

- Add five gallons of fresh gas to the existing gas in the tank, then idle all of it through The Yellow Jacket? OR...

- Convert #50 to electric power, supplied by a nuclear reactor in the bed?

Robroy

- stephen44

- Blue Oval Fan

- Posts: 655

- Joined: Thu Jun 11, 2009 3:28 pm

- Location: Danville, VA

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

I'd get rid of it and use it in the lawnmower ! - let's not add anything to an equation - that we didn't need to.

Imagine Tom's face when you told him you ran over-wintered 6 month gas through the engine

- I would imagine - on a technical point - that over the cold winter it has absorbed a lot of moisture !

-Stephen

thanks

Stephen

(1967 F100, FE352, 2wd, 3 on the tree, flareside)

Stephen

(1967 F100, FE352, 2wd, 3 on the tree, flareside)

- DuckRyder

- Moderator

- Posts: 4924

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Although I've never had an issue with 6 month old gas in anything but a motorcycle, out of an abundance of caution I would probably drain it and run some fresh stuff.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

If it's been in the garage all winter I'd do a simple smell test and if it smelled ok I'd dump in another 5 gallons and go with it. Just the PITA factor would keep me from draining the darned thing.

I probably have three or four year old gas in my fairlane (it doesn't come out much). That's bad.

Jamie

I probably have three or four year old gas in my fairlane (it doesn't come out much). That's bad.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Ranchero50 wrote:If it's been in the garage all winter I'd do a simple smell test and if it smelled ok I'd dump in another 5 gallons and go with it. Just the PITA factor would keep me from draining the darned thing.

Jamie

It's been pretty much sealed up in your tank, and 6-month old gas will be fine.

When I was involved with Scouting, we had an acronym we used a LOT when providing training to new leaders:

KISS = Keep It Simple, Stupid

Don't take that wrong, it's just that sometimes people have a tendency to overthink details...

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good afternoon Stephen, Robert, Jamie, and 70_F100, thanks for your excellent replies!!!

The PITA factor is definitely present here, although the fuel line is easily accessible. It might not be so bad. I just wouldn't know how to get the fuel started through the line (but perhaps it will start on its own).

Stephen, Robert, Jamie, and 70_F100, thanks again for your superb replies!

Robroy

Stephen, I see your point here!stephen44 wrote:after all you've been through

I'd get rid of it and use it in the lawnmower ! - let's not add anything to an equation - that we didn't need to.

HA! Yeah that's true.stephen44 wrote:Imagine Tom's face when you told him you ran over-wintered 6 month gas through the engine

While this seems possible, it might not be very likely in my case. #50 has been in a weatherproof garage all Winter. Still, it's a question of whether the hassle of draining the fuel's worth it, and I'm leaning towards thinking that it is!stephen44 wrote:- I would imagine - on a technical point - that over the cold winter it has absorbed a lot of moisture !

Thanks Robert! That's what I'll do.DuckRyder wrote:Although I've never had an issue with 6 month old gas in anything but a motorcycle, out of an abundance of caution I would probably drain it and run some fresh stuff.

I'm not sure whether or not I'd be able to judge the quality of gas by its smell! Maybe I'd know bad gas when I smelled it. (Why does that sound wrong?)Ranchero50 wrote:If it's been in the garage all winter I'd do a simple smell test and if it smelled ok I'd dump in another 5 gallons and go with it. Just the PITA factor would keep me from draining the darned thing.

The PITA factor is definitely present here, although the fuel line is easily accessible. It might not be so bad. I just wouldn't know how to get the fuel started through the line (but perhaps it will start on its own).

Yikes! That's a nice car.Ranchero50 wrote:I probably have three or four year old gas in my fairlane (it doesn't come out much). That's bad.

You're probably right 70_F100! Still, my question provoked a 50/50 ratio of opinions, so I'll go ahead and replace it. Maybe it's wasted effort, but gosh, it's an expensive engine!70_F100 wrote:It's been pretty much sealed up in your tank, and 6-month old gas will be fine.

That's a great acronym! When I was younger I was more meticulous about every move I made, and I've experimented with relaxing over the years. Sometimes it works out well that way, yet I've noticed that (what seems like) most of the time, things backfire on me when I relax and overlook details. I'll keep experimenting and let y'all know what I think by the time I'm 40!70_F100 wrote:When I was involved with Scouting, we had an acronym we used a LOT when providing training to new leaders:

KISS = Keep It Simple, Stupid

Don't take that wrong, it's just that sometimes people have a tendency to overthink details...

Stephen, Robert, Jamie, and 70_F100, thanks again for your superb replies!

Robroy

- iamthewreckingcrew

- New Member

- Posts: 194

- Joined: Sun Apr 08, 2007 5:36 pm

- Location: Iowa

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Robroy,

I didn't have to blow too hard. I just used lung power. I still don't have a compressor. It was one of those things that actually surprised me because A) It worked. and B) It was easy.

I didn't have to blow too hard. I just used lung power. I still don't have a compressor. It was one of those things that actually surprised me because A) It worked. and B) It was easy.

68 F-100 Short Box 2wd

302/c4/3.50

81 F-100 Long Box 2wd

460/c6/3.00

92 F-150 Lariat 4wd

302/auto couldn't go wrong for $500

302/c4/3.50

81 F-100 Long Box 2wd

460/c6/3.00

92 F-150 Lariat 4wd

302/auto couldn't go wrong for $500

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Well, if you want to do it, I would suggest a outboard fuel line primer bulb and some 3/8" hose. That's how I transferred heating oil for the garage all winter. The bulb gets the fuel flowing, gravity keeps it going.

I did the garden hose thing once... (we need a barfing smiley)

Jamie

I did the garden hose thing once... (we need a barfing smiley)

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

-

Alvin in AZ

- Blue Oval Fan

- Posts: 583

- Joined: Thu Feb 19, 2009 3:50 pm

- Location: Gadsden Purchase

- Contact:

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

http://shop.oreillyauto.com/ProductDeta ... yCode=3487

A guy can put his finger over the "down hill hose" end

while releasing the bulb to fill the bulb up quicker.

x2 what "70" said, under any circumstances other than this one! LOL :)

Aircooled VW's would act up with just two to three month old gas. :/

My 360FE won't act up with even ~year-old gas out of parts trucks! :)

Alvin in AZ

ps- Jamie types faster than I do. ;)

A guy can put his finger over the "down hill hose" end

while releasing the bulb to fill the bulb up quicker.

x2 what "70" said, under any circumstances other than this one! LOL :)

Aircooled VW's would act up with just two to three month old gas. :/

My 360FE won't act up with even ~year-old gas out of parts trucks! :)

Alvin in AZ

ps- Jamie types faster than I do. ;)

-

Fordnatic

- Preferred User

- Posts: 274

- Joined: Wed Dec 17, 2008 7:29 am

- Location: Anchorage, Alaska

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Don't make it too hard. If you just pull a rubber line apart down low it will gravity flow out. If you want to speed it up take your blow nozzle and wrap it with a rag, stuff it in the fuel fuller and give it a couple spurts. This works well, any excess pressure leaks out around the rag avoiding damage to the tank.

As always, be VERY careful about ignition sources when messing around with gas. Remember the fumes stay low and can ignite from several feet away. I always prefer to do this outside, as if there is a fire at least the building is safe. I feel the need to pass along a story. A good friend was working on a nice project (although a Chevy-it was a shortbed 4x4 mid 70's vintage) in a really nice 3 bay plus paint booth shop. He was removing the fuel tank after having drained the majority of the fuel. While lowering it and taking it out from under the pickup, the gas sloshed (or something) and caused him to stumble and drop the tank. There was a trouble light that he was using laying on the floor, and as the tank dropped it broke the bulb and ignited the whole works. He only had time to push one vehicle out before the whole thing went up. The building and 4 vehicles were a total loss.

I have a similar story, although luckily it turned out better. I was working on the exhaust of my 70 F100 when I was 16. I was at home on our ranch alone-25 miles from the nearest fire dept. I was grinding on the exhaust on the welding table, with my pickup up on 4 jackstands. There was a combine and another pickup in the shop, as well as a 40 year collection of tools and equipment. There was a container with gas that we used for parts washing nearby, and suddenly I noticed the sparks from the grinder shooting right on it. I stopped the grinder and to my horror could see flames coming from around the lid of the gas container. It was a 2.5 gal plastic jug just refilled. I ran over and grabbed it by the handle (with my welding gloves on) and chucked it outside the door. It landed on the inevitable pile of junk that collects out in front of a shop (semi truck tires, wood, sheetmetal, and a couple 55 gal drums of old oil among other things) and burst open into flames, igniting that whole pile. I emptied a fire ext on it with no effect. There was a faucet with hose right there, it didn't have much effect either. I phoned the nearest neighbor (5 miles away) and his wife said she didn't know where he was but would try to find him. Meanwhile, the entire front wall of the 40x60 shop was in flames. The 2 semi tires were leaning against the wall and you know how hot rubber burns. The two oil drums were bulging from the heat. We had a loader with a large bucket and grapple which I sprinted for. It barely turned over, the battery was almost dead. Thank God it fired, and I plunged into that burning pile of debri, closing the grapple and dumping the load in the driveway. After several times of this I had it mostly cleared away from the building except for the drums and the tires. I got a heavy coat and the welding gloves and grabbed the tires and rolled them away from the front wall of the shop. Then with most of the heat gone I used the hose to put the actual wood wall of the shop out. A few minutes later the neighbor finally came and just shook his head as he drove around several piles of burning rubble in the driveway and took in the still smoldering charred front of the shop!

So many things could have gone different. We made a parts washer and started buying solvent instead of cleaning with gas. If the pile of junk wasn't in front of the shop the gas jug would have harmlessly burned on the ground. If the loader wouldn't have started the whole building would have gone up. We washed parts in gas for years without a problem previously, but since then I have become much more careful.

As always, be VERY careful about ignition sources when messing around with gas. Remember the fumes stay low and can ignite from several feet away. I always prefer to do this outside, as if there is a fire at least the building is safe. I feel the need to pass along a story. A good friend was working on a nice project (although a Chevy-it was a shortbed 4x4 mid 70's vintage) in a really nice 3 bay plus paint booth shop. He was removing the fuel tank after having drained the majority of the fuel. While lowering it and taking it out from under the pickup, the gas sloshed (or something) and caused him to stumble and drop the tank. There was a trouble light that he was using laying on the floor, and as the tank dropped it broke the bulb and ignited the whole works. He only had time to push one vehicle out before the whole thing went up. The building and 4 vehicles were a total loss.

I have a similar story, although luckily it turned out better. I was working on the exhaust of my 70 F100 when I was 16. I was at home on our ranch alone-25 miles from the nearest fire dept. I was grinding on the exhaust on the welding table, with my pickup up on 4 jackstands. There was a combine and another pickup in the shop, as well as a 40 year collection of tools and equipment. There was a container with gas that we used for parts washing nearby, and suddenly I noticed the sparks from the grinder shooting right on it. I stopped the grinder and to my horror could see flames coming from around the lid of the gas container. It was a 2.5 gal plastic jug just refilled. I ran over and grabbed it by the handle (with my welding gloves on) and chucked it outside the door. It landed on the inevitable pile of junk that collects out in front of a shop (semi truck tires, wood, sheetmetal, and a couple 55 gal drums of old oil among other things) and burst open into flames, igniting that whole pile. I emptied a fire ext on it with no effect. There was a faucet with hose right there, it didn't have much effect either. I phoned the nearest neighbor (5 miles away) and his wife said she didn't know where he was but would try to find him. Meanwhile, the entire front wall of the 40x60 shop was in flames. The 2 semi tires were leaning against the wall and you know how hot rubber burns. The two oil drums were bulging from the heat. We had a loader with a large bucket and grapple which I sprinted for. It barely turned over, the battery was almost dead. Thank God it fired, and I plunged into that burning pile of debri, closing the grapple and dumping the load in the driveway. After several times of this I had it mostly cleared away from the building except for the drums and the tires. I got a heavy coat and the welding gloves and grabbed the tires and rolled them away from the front wall of the shop. Then with most of the heat gone I used the hose to put the actual wood wall of the shop out. A few minutes later the neighbor finally came and just shook his head as he drove around several piles of burning rubble in the driveway and took in the still smoldering charred front of the shop!

So many things could have gone different. We made a parts washer and started buying solvent instead of cleaning with gas. If the pile of junk wasn't in front of the shop the gas jug would have harmlessly burned on the ground. If the loader wouldn't have started the whole building would have gone up. We washed parts in gas for years without a problem previously, but since then I have become much more careful.

70F100: 410 Merc with tri-power, close ratio toploader, 4.56 detroit locker 9"

68F100 4x4: 390, 4 spd/NP 205, Rancho 4" urethane susp, 35x12.50 All Terrain T/A's

55F100

01F150 Daily Driver: TP tunes, AF1 intake, elec fans, Magnaflow exh, underdrive pulleys, Centerlines

68F100 4x4: 390, 4 spd/NP 205, Rancho 4" urethane susp, 35x12.50 All Terrain T/A's

55F100

01F150 Daily Driver: TP tunes, AF1 intake, elec fans, Magnaflow exh, underdrive pulleys, Centerlines

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: 390FE (406ci) for #50, built by Tom Lucas at FE Specialties.

Good afternoon!

I removed the bell housing and Browell Bellhousing alignment tool and re-installed them very carefully, checking all the surfaces for subtle defects (like squashed bugs). This time, the tool indicated a lesser misalignment--it looked about half as bad as before.

And like before, the misalignment followed the crankshaft angle when I rotated the crankshaft. In other words, if the alignment tool indicated a gap at the bottom of the bellhousing hole, turning the crankshaft 180 degrees rotated the gap to the top.

I took the bell housing off again and looked at the tool very carefully. I found an obvious gap between the base of the tool and the surface that's normally flush with the flywheel!

I then installed the Browell tool on my old crankshaft, and found no gap between those surfaces at all.

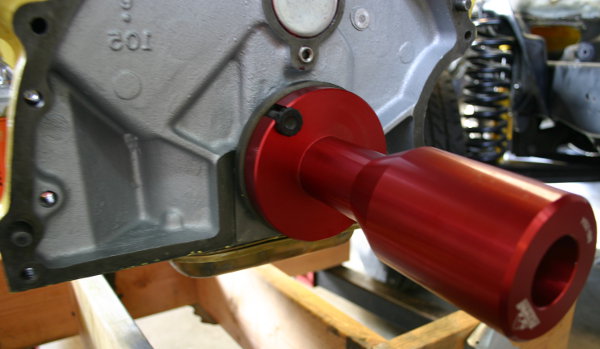

In these three photos, the Browell tool's on the old crankshaft, and I'm using a thin saw blade to indicate the gap--or lack thereof--between the tool's base and the flywheel mounting surface. You can see that there's no gap; I'm not able to slide the saw blade in between the surfaces. I took great care not to scratch the surfaces with the blade!

In contrast, here's the Browell tool on the new crankshaft. It's fully installed; the bolts are snug. And the saw blade indicates the obvious gap!

My theory's that the Browell tool's giving a variety of readings while installed on the new crankshaft, because it's making contact with the crankshaft on a thin ring of surface area (the outer edge of the protrusion that houses the pilot bearing).

A close inspection of both crankshafts shows that they ARE slightly different in that area. The new crankshaft's protrusion sticks out slightly more than the old one! Just enough to keep the Browell tool from working as designed.

Four possibilities come to mind:

Thanks very much for your superb advice!!!

Robroy

I removed the bell housing and Browell Bellhousing alignment tool and re-installed them very carefully, checking all the surfaces for subtle defects (like squashed bugs). This time, the tool indicated a lesser misalignment--it looked about half as bad as before.

And like before, the misalignment followed the crankshaft angle when I rotated the crankshaft. In other words, if the alignment tool indicated a gap at the bottom of the bellhousing hole, turning the crankshaft 180 degrees rotated the gap to the top.

I took the bell housing off again and looked at the tool very carefully. I found an obvious gap between the base of the tool and the surface that's normally flush with the flywheel!

I then installed the Browell tool on my old crankshaft, and found no gap between those surfaces at all.

In these three photos, the Browell tool's on the old crankshaft, and I'm using a thin saw blade to indicate the gap--or lack thereof--between the tool's base and the flywheel mounting surface. You can see that there's no gap; I'm not able to slide the saw blade in between the surfaces. I took great care not to scratch the surfaces with the blade!

In contrast, here's the Browell tool on the new crankshaft. It's fully installed; the bolts are snug. And the saw blade indicates the obvious gap!

My theory's that the Browell tool's giving a variety of readings while installed on the new crankshaft, because it's making contact with the crankshaft on a thin ring of surface area (the outer edge of the protrusion that houses the pilot bearing).

A close inspection of both crankshafts shows that they ARE slightly different in that area. The new crankshaft's protrusion sticks out slightly more than the old one! Just enough to keep the Browell tool from working as designed.

Four possibilities come to mind:

- Forget about using the Browell tool. Put it all together and be happy.

- Insert a uniform metal disc between the mating surfaces. This should push the tool away from the protrusion enough to clear it and might yield an accurate reading.

- Contact Browell to see if they're aware of this issue. Maybe they have a workaround (like a metal disc).

- Use the traditional method of measuring bell housing alignment, as documented in the Ford shop manual. I'd have to gain access to one of the special dial gauges shown in the manual.

Thanks very much for your superb advice!!!

Robroy